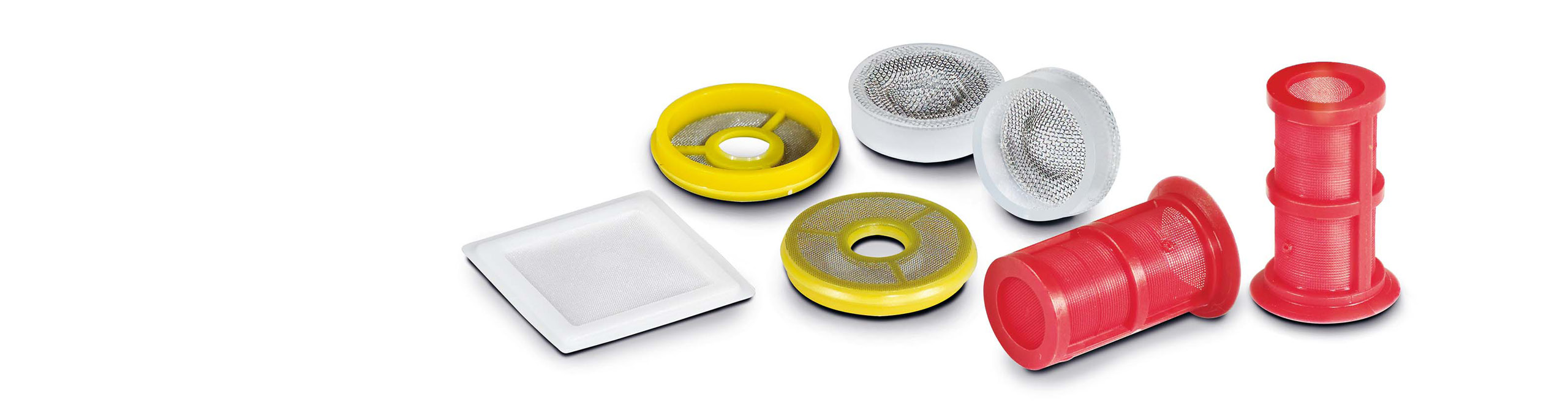

Plastic technology

Injection moulding is one of our core competencies

70 years of experience make us a particularly reliable partner with the corresponding core competencies.

We manufacture filters and sieves made of plastic with experience of over 70 years. Therefore, plastics technology is one of our core competences. We manufacture and supply filters and strainers in various shapes, sizes and plastic compositions. We manufacture the tools required for this purpose in our own in-house tool manufacture.

We handle the following materials:

- Standard thermoplastics PE, PP

- Technical thermoplastics PA, POM, PC, ABS

- Construction / high power materials PPA, PPS, PEEK, GRIVORY

Technical equipment

- 24 injection moulding machines from12to to 130to bolts

- Clamping surface from 100x130 mm to 400x540 mm

- Shot weight from 2 g/PS to 194 g/PS

- Horizontal, vertical handling, or with a round table

- Handling with fully automated or manual insert and extraction ability depending on the batch size